As one of the Group’s key technologies, printing is our primary area of expertise. We have developed this know-how over the years, so that you can benefit from the most competitive and efficient processes on the market.

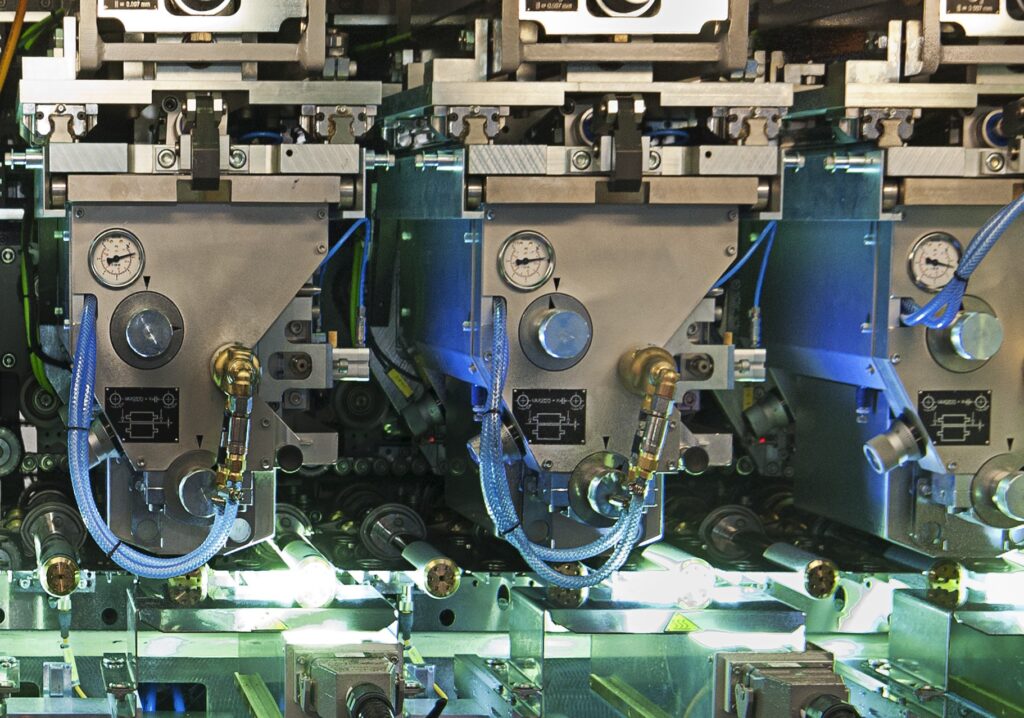

Dry offset printing – a robust, fast and highly economical technology :

One of the fastest printing technologies available, so you can increase your production output at a highly competitive cost, thanks in particular to minimal downtime.

Like all the technologies we refine at Polytype, this process offers the advantage of working directly on the product. Without the need for labeling material, you reduce your costs while promoting an environmentally-friendly approach.

As the historic technology on which our group was built, this process has been fine-tuned down to the last detail, so that you can benefit from all our expertise. Today, we are proud to be the world leaders in this type of technology. And to make life easier for you, our technological processes are always offered on user-friendly machines.

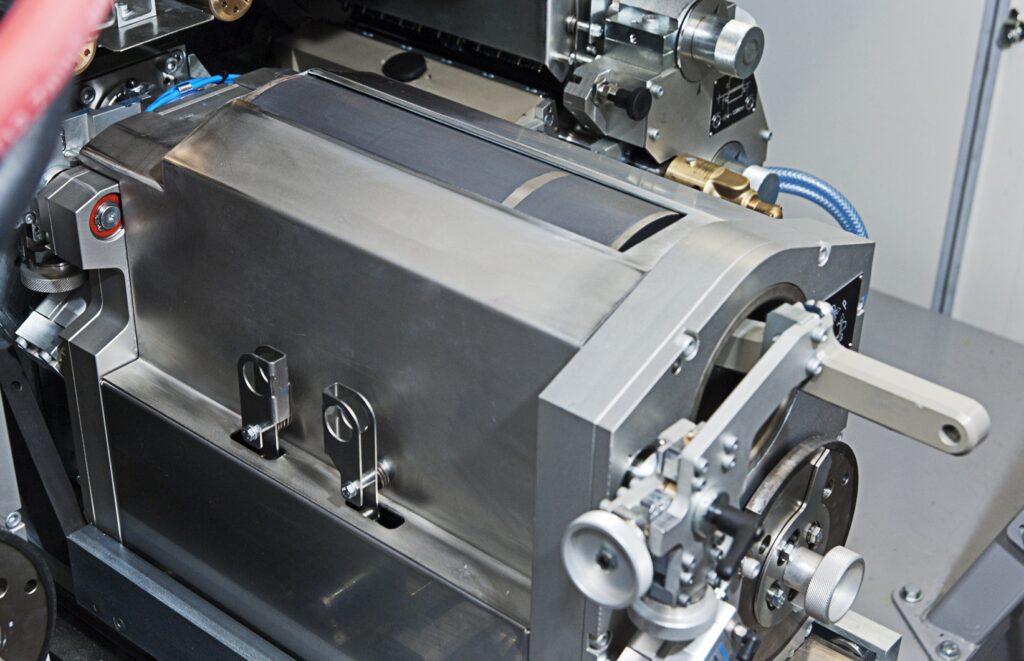

Prime Offset considerably expands the printing options, although the dry offset printing process remains an alternative on the printing machine. Prime Offset enables four-colour printing in the highest quality and speed.

Support your marketing strategy with high-quality products and packaging.

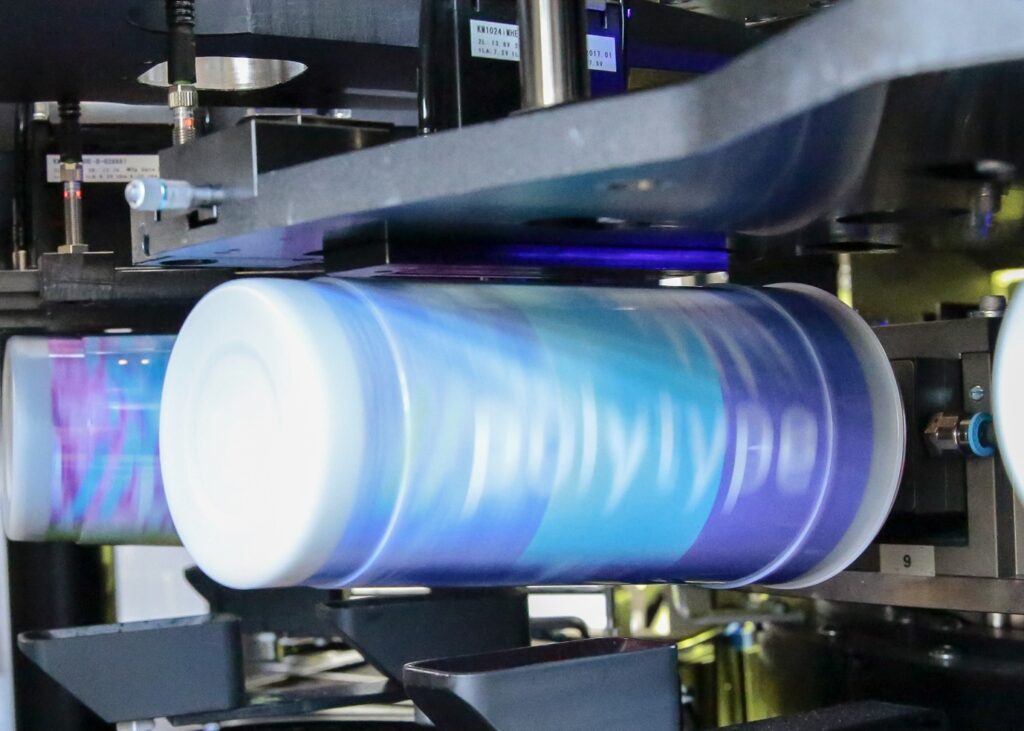

Flexo printing is the most commonly used four-color direct printing process for tubes and sleeves. The flexible printing plates enable high ink transfer to the substrate.

The ideal solution for embellishing your flexible products with a high-quality four-color printing system.

Screen printing is also a printing process in which each color is dried after printing.

The special feature of screen printing is the high layer thickness, which allows colored or transparent substrates to be printed, whereby the color stands out clearly from the substrate.

As a direct-to-product printing technology, this process offers a unique advantage in terms of customization and speed of execution. The ideal solution for producing smaller and specific series, giving a unique and personal touch to each batch in your series. QR codes, serial numbers, names, images, print variable data as you wish.

This printing technology is also among the most qualitative in terms of photorealistic rendering. Finally, it is also a technological process which makes it possible to reduce losses linked to the start of a new series while considerably reducing the pre-printing stages.

On top of that, from a marketing and business model perspective, this technology is one of the most interesting, allowing you to personalize your messages in detail while offering personalized b2b and b2c interactions through a digital supply chain. Online, for example, offer your partners and customers the opportunity to design their personalized product in just a few clicks.

A proven technological process to give a shiny and/or metallic touch to your products and packaging. Mainly used for luxury goods, this technology allows you to embellish your series to distinguish them from more classic goods.

With a process based on pressure and heat, this technology operates a selective transfer of lines or even letters from a metallized sheet, as the direct printing does not make it possible to give a sufficiently realistic or qualitative metallic or shiny effect.

Are you navigating a specific industry landscape? Discover the key sectors we’ve been passionately serving for over two decades.

If your industry isn’t listed, worry not, our advisors are ready to address your inquiries and find the perfect solution tailored to your field.

Our commitment to excellence extends to providing personalized solutions for businesses across various sectors.

Whether you have questions, feedback, or partnership inquiries, we’re here to listen.

Reach out to us and let’s start a conversation that leads to possibilities.